|

Home | Company | Solutions | References & Markets | News & Events | Support | Contact |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| NL FR EN DE CZ | June 2005 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Dear reader, Our third edition of the SCIA Conference has been another great success. Please read more about it in this last eNews before the holidays. We wish you a lot of reading pleasure and also a sunny and relaxing summer break! We will see each other again in September with the next eNews edition. Here are this month's topics: |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SCIA Corporate News: Cost optimisation in Construction | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

On the 19th of May, SCIA organized in Brussels a well-attended conference on ‘Cost

Optimisation in Construction’. In a world where globalisation is reality, most construction companies are confronted with the challenge to find innovative ways to realize higher productivity. The guest speakers of the conference, all authorities in their domain and speaking out of their daily experience, came up with solutions for cost-effectiveness in construction. Several points of view came up, they were subdivided in 3 major sectors: virtual modelling, material choice and construction processes. On the 19th of May, SCIA organized in Brussels a well-attended conference on ‘Cost

Optimisation in Construction’. In a world where globalisation is reality, most construction companies are confronted with the challenge to find innovative ways to realize higher productivity. The guest speakers of the conference, all authorities in their domain and speaking out of their daily experience, came up with solutions for cost-effectiveness in construction. Several points of view came up, they were subdivided in 3 major sectors: virtual modelling, material choice and construction processes.Virtual modelling  Eighty percent of costs are fixed during the design phase. Therefore digital modelling of a structure deserves great attention; it forms the input for the engineering design, to find out all load resistance optimal schemes, building regulation compliance and construction details. Yet it is also used for generating the material cost through an automated precise bill of material, coming from the 3D CAD model. The Building Information Model (BIM) is rapidly gaining acceptance in the construction industry, where building partners exchange detailed intelligent information. Eighty percent of costs are fixed during the design phase. Therefore digital modelling of a structure deserves great attention; it forms the input for the engineering design, to find out all load resistance optimal schemes, building regulation compliance and construction details. Yet it is also used for generating the material cost through an automated precise bill of material, coming from the 3D CAD model. The Building Information Model (BIM) is rapidly gaining acceptance in the construction industry, where building partners exchange detailed intelligent information.Renewing materials The use of materials is the second cost optimisation solution. Newly developed materials and ingeniously combined existing materials, as for example mixed steel-concrete, are used in bridges, columns and floors to reduce the overall material cost. Building systems such as pre-cast, constructive elements or mixed floors (Arcelor) increase the free span, while reducing the material consumption. Construction methods and procedures The third cost reducer is related to process improvement: concerning building systems (pre-fabrication), project data sharing, the fabrication process, a financial partnership (public-private cooperation) or any transformation of how a company (or group of companies) is working, the improvement demands strong management skills.  User Contest 2005 During the conference the winners of the SCIA User Contest 2005 were celebrated. The projects illustrated how SCIA is a provider of tools supporting cost optimisation. SCIA proved also to be a partner for auditing the design, material or process innovations.

Presentations (PDF): |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SCIA - IWT Project on Structural Aluminium | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

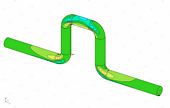

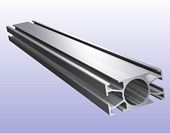

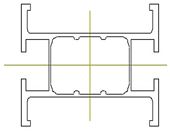

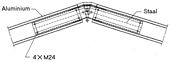

In order to anticipate the steadily increasing market demand for aluminium in constructions, SCIA has started a research and development project for innovation purposes. This project is financially supported by the IWT of Flanders (Institute for the Promotion of Innovation through Science and Technology). In order to anticipate the steadily increasing market demand for aluminium in constructions, SCIA has started a research and development project for innovation purposes. This project is financially supported by the IWT of Flanders (Institute for the Promotion of Innovation through Science and Technology).The SCIA goal is to develop an advanced practical CAE software solution for the future needs of designers in the structural aluminium world. This requires an important extension of the existing CAE software with new functionalities, new codes, regulations and methods that are typical for aluminium. The use of aluminium in constructions has a lot of very specific (and deviating from other materials) characteristics: arbitrary sections (formed by extrusion), very thin-walled sections (with buckling behaviour), highly reformable, joints of several sections, special connections with steel elements. Aluminium is a more complex material than e.g. steel because it needs more parameters and it has another behaviour. Therefore there is a strong need for practical development methods. This will be the essence of the investigation. With respect to the strength calculation of aluminium sections and corresponding connections, we focus on three themes:  A. Local buckling stability of complex cross-section forms and the translation to useful equivalent calculation values and design checks. A. Local buckling stability of complex cross-section forms and the translation to useful equivalent calculation values and design checks.One of the distinctive characteristics of complex thin-walled aluminium sections is that the plate thickness is relatively small. The relation width/thickness of the composing plate elements has a tendency to be rather large. This implies that these elements, which are subjected to compression forces, will become unstable due to stresses that are lower than the elastic limit tension. The European regulations for the design of aluminium supporting systems (EC9) have incorporated the method of the effective cross-section properties for taking into account this local buckling effect. This results in a classification of the cross-section B. Added properties of the cross-section [e.g. HAZ (Heat Affected Zones)] and the conversion to calculation values In the design of welded aluminium constructions it is necessary to take into account the decrease of the strength properties that occur in the proximity of the weldings. The affected zone is situated around the welding. The degree of the softening and the size of this zone depends, among other things, of the chosen type of aluminium, of the welding type (corner welding, stub welding) and the welding method  C. Automatic conversion of the cross-section forms to the finite element method C. Automatic conversion of the cross-section forms to the finite element methodA method for obtaining the automatic explosion of a selected detail (e.g. a connection) to a new calculation model with 3D elements (shells or solids) starting from a linear beam model. The internal forces of the beam model are taken into account as loads on the finite element model. After introducing the boundary conditions, the model is calculated. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| In Germany, the leaders of the construction industry raise their heads | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shortly after the optimism announced by the number one of the sector ‘Hochtief’ during this year, it was the turn of the number two ‘Bilfinger Berger’ for informing about a significant progression of its results. Shortly after the optimism announced by the number one of the sector ‘Hochtief’ during this year, it was the turn of the number two ‘Bilfinger Berger’ for informing about a significant progression of its results. Last Thursday, Bilfinger Berger communicated the forecast for its sales turnover 2005. In spite of the first quarter with a net loss of 3 million euros, otherwise expected by the analysts, they await a sales turnover of 6,7 billion euros, of which 6,5 billion euros have been noted already. They also count on a significant progression of their net income. With an extreme progression of 3% of their sales turnover from January until the end of March and especially with the jump of 31% of order entries, the group ensured to know an "exceptionally good evolution". Last Thursday, Bilfinger Berger communicated the forecast for its sales turnover 2005. In spite of the first quarter with a net loss of 3 million euros, otherwise expected by the analysts, they await a sales turnover of 6,7 billion euros, of which 6,5 billion euros have been noted already. They also count on a significant progression of their net income. With an extreme progression of 3% of their sales turnover from January until the end of March and especially with the jump of 31% of order entries, the group ensured to know an "exceptionally good evolution".The day before, competitor ‘Hochtief’ had already raised its result forecast for 2005 after having seen its benefits strongly progressing in the first quarter. Two ‘good news’ messages which give again hope within the German construction sector, being in a crisis since the collapse of the real-estate market following the reunification of the country in 1990. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| PT Baja Engineering Indonesia - Roundabout Velmolenweg Uden (NL) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

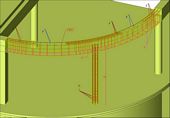

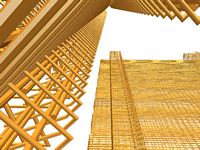

Client: Province of Noord-Brabant Client: Province of Noord-BrabantContractor: Ballast Nedam Infra Zuid Oost Engineering client: Holland Railconsult Engineering contractor: Infra Consult & Engineering Subcontractor engineering detailing: Structural Concrete Engineering & PT Baja Engineering Indonesia Used software: Allplan Engineering  The project comprises the building of two fairly similar tunnels for pedestrians, with a shell structure in between and a roundabout above the tunnels. The project comprises the building of two fairly similar tunnels for pedestrians, with a shell structure in between and a roundabout above the tunnels.The tunnels will be built inside a sheet wall structure to secure excavation and with underwater concrete at the bottom in order to secure water pressure during construction. Structural Concrete Engineering and PT Baja Engineering Indonesia executed the detail engineering that included: 3d survey of contract drawings, preparation of dimension drawings, preparation of rebar drawings, preparation of bending schedules of the rebar. Tunnels The length of the two fairly similar tunnels, running parallel underneath the roundabout, is 155m. Each tunnel is divided into 7 sections of which 3 parts are closed with a deck structure. At the connection with the shell structure in the middle of the roundabout, the tunnel section has a large opening. From the engineering point of view, this is the most interesting part of the tunnel. The shape of the shell, curved in all directions, is connected to an inclined wall structure. The top of the wall structure is also bent, matching the curves of the shell structure.  The floor slabs will be cast on top of the under water concrete, attached with welded dowels to the sheet wall structure. The floor slabs will be cast on top of the under water concrete, attached with welded dowels to the sheet wall structure.The decks of part 3, 4 and 5 are supported by the sheet wall structure. The walls consist of inclined prefab concrete elements that cover the sheet wall structure completely. Rain water and water from leakage is a collected in a water containing structure situated in part 2 of the westly tunnel. The project will be completed in June 2005.  Detailing process Detailing processStructural Concrete Engineering and PT Baja Engineering Indonesia started this job with a 3d check on critical parts of the structure. After the check and approval by our client of our findings, the dimension drawings were prepared. In total 45 A0 size drawings were prepared for 11 tunnel sections and 1 shell structure. After approval by our client of the dimension drawings the rebar drawings were prepared. Over 375 ton of rebar was designed. Again 45 A0 size drawings were prepared. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Tips & Tricks: Select elements by multiple properties in SCIA.ESA PT | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

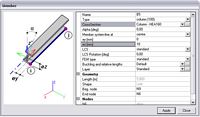

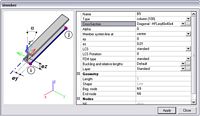

In SCIA.ESA PT 5.1 it is possible to select elements by multiple properties using the Select elements by more properties button In SCIA.ESA PT 5.1 it is possible to select elements by multiple properties using the Select elements by more properties button First of all, it is needed to select a master entity, for example a column of the structure. Next, it is possible to highlight multiple properties using the CTRL button. Using the [Apply] button, the selection is made and the dialog box appears again. This makes it possible to select for example a different Cross Section like a diagonal. Using the [Close] button, the multiple selection command is ended. The end result for this example is that all Columns with an eccentricity ez and all Diagonals are selected.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| About this SCIA eNews | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

SCIA Group NV - Industrieweg 1007 - B-3540 Herk-de-Stad Tel: +32 (13) 55.17.75 - Fax:+32 (13) 55.41.75 |

Copyright

© 2005 SCIA Group nv |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||